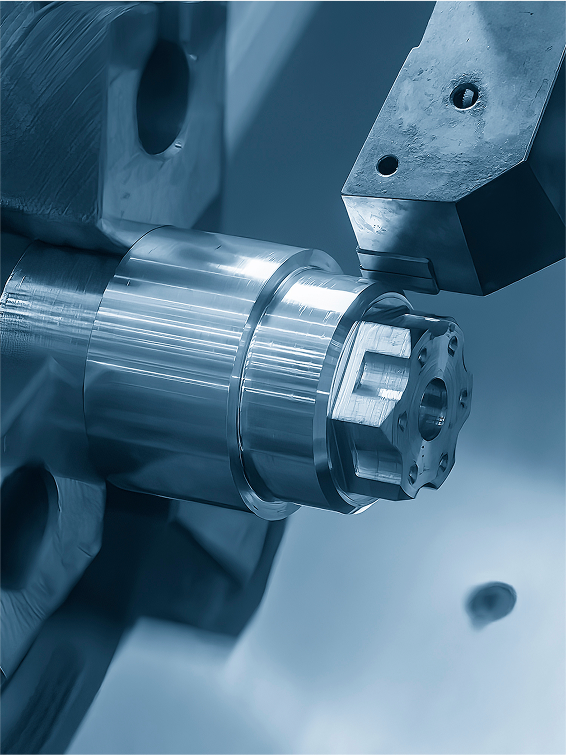

Get precision parts built for high-stakes industries—fast. At Hartmann’s, we understand that aerospace material specification is just as critical as the final tolerance. We deliver custom metal and plastic CNC machined components. ISO 9001:2015. AS9100D. ITAR registered. Get a Quote in 72 hours.

Looking for CNC Aerospace Parts?

In the aerospace industry, performance and compliance begin with the specifications for aerospace materials. Before machining begins, engineers and manufacturers must understand how the selected material responds to load, heat, and stress, and how these behaviors impact the machining process.

For alloys like titanium and Inconel, specifications go beyond dimensions. They define heat treatment, grain structure, surface condition, and mechanical behavior. These factors influence how the material can be cut, how it will hold tolerance, and whether it will meet long-term performance expectations.

Tolerances alone don’t define aerospace-quality parts. Successful outcomes require synchronizing material properties, machining methods, and post-process stability. In flight-critical applications, suppliers must consider factors such as creep resistance, fatigue life, and material consistency across production runs to ensure parts perform reliably over the component’s lifespan.

Being to Spec is More Than Meeting a List of Properties

Aerospace components operate under pressure, heat, vibration, and time. That’s why most of the aerospace material specifications are based on the Society of Automotive Engineers (SAE) standards, which typically include the following requirements:

- Precise chemical composition

- Heat treatment condition

- Grain size and orientation

- Surface finish requirements

- Material consistency

This level of detail ensures performance under extreme operating conditions.

Titanium and Inconel: Spec-Driven, Not Price-Driven

Titanium and Inconel aren’t selected for cost—they’re specified because performance demands it.

- Titanium (Ti-6Al-4V) is lightweight, strong, and corrosion-resistant. Ideal for airframes, brackets, and high-stress structural parts.

- Inconel 718 can withstand heat above 700°C. This makes it essential for turbine parts, combustor cases, and engine components.

Each comes with different machining behaviors, varying responses to heat, and distinct inspection requirements.

The Right Toolpath Starts with the Right Aerospace Material Specification

Titanium and Inconel are high-performance materials, but they are unforgiving in their use. That means toolpaths must align with what the aerospace material can take.

Titanium:

- Conducts heat poorly, causing tools to overheat

- High material strength results in elevated cutting forces

- Requires consistent chip load and ample coolant to prevent alpha-case formation

Inconel:

- Work hardens rapidly during machining

- Requires continuous cutting and high-pressure coolant

- Performs best with ceramic or CBN tooling

Looking for CNC Aerospace Parts?

Inspection and Monitoring Are Non-Negotiable

In aerospace, every material lot must be traceable. The Society of Automotive Engineers builds this into its standards. The SAE continuously updates standards to reflect new findings or practices.

At inspection, shops must:

- Confirm grain flow and heat-affected zones

- Validate surface integrity and profile tolerances

- Provide records that link back to the original material certifications

- Document every probe, tool, and measurement system used

Why Aerospace Material Specification Matters

Precision alone doesn’t guarantee a flight-ready part. Without full alignment with the aerospace material specifications, teams often face the problems below, which could be avoided with a better understanding of the material.

- Overheating titanium during machining can lead to alpha-case formation, reducing fatigue strength.

- Allowing Inconel to dwell mid-cut may cause unintended work hardening and increase the risk of surface cracking.

- Mixing or mislabeling bar stock breaks consistency and can compromise AS9100 compliance.

Know the Material, Not Just the Dimension

Material specifications should inform decisions across programming, machining, inspection, and documentation.

The aerospace industry doesn’t leave room for assumptions. If your next project involves titanium, Inconel, or other high-performance alloys, make sure the material specs is more than a footnote.

At Hartmann’s, we speak the language of materials and the standards that govern them. We know the difference between cutting to a dimension and manufacturing to a specifications.

Let’s discuss your next critical component. Contact us to review your aerospace material spec together.