Comprehensive precision machining services

Because Hartmann’s is for companies that refuse to compromise on cost, quality, accuracy, or speed, we have invested in delivering all the precision machining services you need to thrive.

Whatever your performance needs, reach out. Our expert engineers are ready to figure out the optimal custom solution.

See what you can achieve when you partner with the best.

01

Submit RFQ

02

Purchase Order

03

Collaborate with Hartmann’s Experts

04

On-Time Delivery of High-Precision Parts

05

Ongoing Partnership

The Hartmann's Process

To provide a seamless customer experience, we have developed this easy 5-step process.

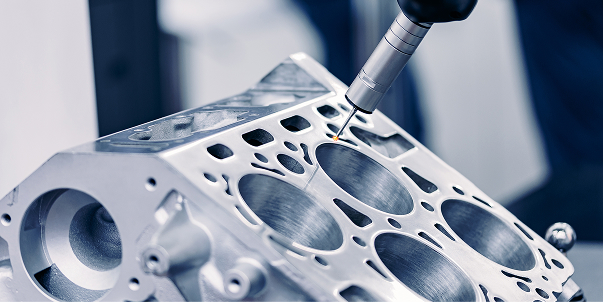

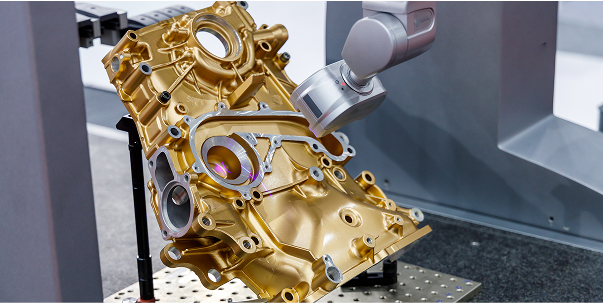

CNC Machining

Exceptional CNC machining is what put Hartmann’s on the map.

With Hartmann’s CNC machining, cutting-edge technology and traditional craftsmanship come together to deliver unbeatable quality at unrivaled efficiency.

· Scrap rate of less than 3%

· Tolerance of 0.0002”

· Production runs from a single part to hundreds of thousands

· Rigorous quality control

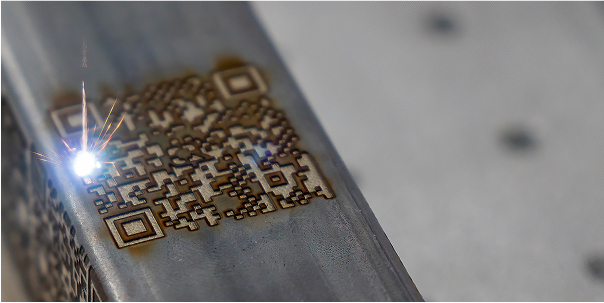

Laser Etching

Get high-precision laser etching services on a variety of materials.

Whether you need precision engraving for your part or to add an aesthetic finish, we’ve got you covered.

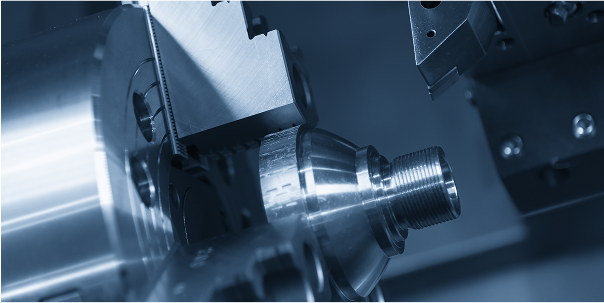

Metal Fabrication

Whatever part you need, Hartmann’s can make it.

With our state-of-the-art facility, we can leverage a diverse array of metal fabrication techniques to get you the precision part you need at unbeatable efficiency.

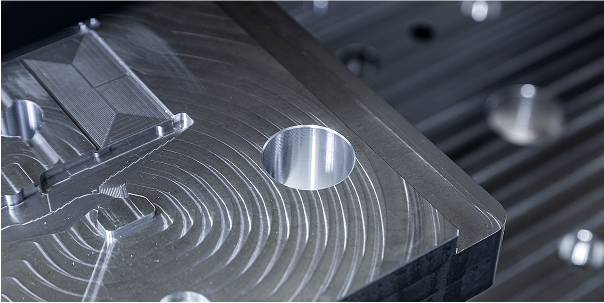

Rebuilds

Hartmann’s has been rebuilding engines and other complex parts since our first day in 1955.

No matter the size, complexity, or current status of your rebuild project, our engineers will get you running at maximum efficiency.

Metal Finishing

Whatever your durability, corrosivity, conductivity, or other performance needs, we’ve got you covered.

Hartmann’s experts will design and implement the right metal finish for your unique job.

Welding

Hartmann’s offers a full array of welding services.

Whether you need a one-off or a high-volume run, our services meet the quality standards of companies in tough industries like aerospace and energy.

Engineering & CAD Applications

We leverage the latest software to design custom solutions tailored specifically for your design and manufacturing needs.

We’re ready to meet the needs of any facility, with a special expertise in design for cost-effective, dependable automation.

Reverse Engineering

Hartmann’s is so confident in its engineering expertise that we make partnering with us as simple as possible.

You give us the part you need replicated, and we’ll figure out the most efficient way to manufacture it. Guaranteed.

Quality Control

At Hartmann’s, it only counts as quality control if our work meets your quality standards.

That’s why with every job we develop rigorous quality assurance protocols that guarantee your standards are met every time.