Aerospace Precision Engineering: A Practical Guide

Aerospace precision engineering demands consistency under pressure. From turbine inserts to satellite brackets, every part must meet exact specifications and withstand extreme conditions like vibration, heat, and force.

When tolerances are measured in microns, success depends on more than just high-end machines. It depends on a combination of discipline, tightly controlled processes, strategic planning, and trust between engineers and manufacturers to ensure performance at altitude and beyond.

The Meaning of Aerospace Precision Engineering

Aerospace precision engineering demands ultra-tight tolerances, often as precise as ±0.0002 inches—where even the smallest deviation can compromise a part’s performance.

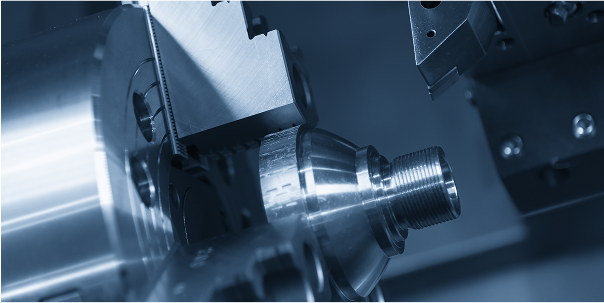

Precision begins with the machining environment. Aerospace parts are often produced in temperature-controlled shops using CNC equipment that can maintain accuracy down to a few microns. 5-axis lathes, live-tooling centers, advanced mills, and other equipment allow manufacturers to tackle complex geometries without sacrificing dimensional stability.

Accuracy is equally important as repeatability. Producing one perfect part isn’t the goal, producing hundreds or thousands of identical parts is. That’s why certified shops often use CMMs (Coordinate Measuring Machines), 3D laser scanners, and digital inspection systems to validate dimensions and catch discrepancies in real time.

Process Discipline Makes All the Difference

In aerospace projects, even a minor defect can ground a system. That’s why repeatable, well-documented processes matter as much as machining capability.

Aerospace-qualified shops must follow rigorous documentation procedures—often under certifications like AS9100D and ISO 9001:2015. These standards govern everything, from material tracking or risk management and inspection. Whether manufacturing a new design, a reverse-engineered legacy part, or a low-volume prototype, the entire process should be built for transparency and control.

Advanced planning is also key. Aerospace jobs typically involve long lead times, extensive documentation (drawings, models, CAD/CAM data), and secondary processes like heat treating, anodizing, or lapping. Without meticulous capacity planning and program management, delays and cost overruns will quickly follow.

Material Mastery: The Hidden Variable

Every metal behaves differently under pressure, temperature, and load—and aerospace applications push materials to their limits.

From lightweight aluminum alloys used in fuselages to heat-resistant Inconel in jet engines, material selection helps account for performance, machinability, and long-term durability. Engineers must understand how to cut, finish, and treat each metal or composite to preserve its properties and ensure longevity in demanding environments.

Poor-quality or uncertified materials can lead to structural failures, missed compliance requirements, or even grounding of aircraft. That’s why certified aerospace components often require full traceability and must meet government or defense compliance standards. To support this, many shops work only with vetted, U.S.-based suppliers.

Precision Requires Partnership

No matter how skilled the manufacturing team or how sophisticated the machines, delivering flight-critical parts depends on trust. That trust is built over time through clear communication, shared problem-solving, and a deep understanding of both technical and operational requirements.

Experienced suppliers don’t just follow prints. They collaborate with engineers to improve manufacturability, suggest smarter material choices, and redesign outdated parts without CAD. This partnership can prevent delays, lower costs, and ultimately improve part performance.

Trust is also essential for security and compliance. Beyond certifications, buyers need to know that their supplier will respond quickly, raise red flags early, and follow through when issues arise.

Aerospace projects leave no room for error. Behind every successful launch, flight, and landing is a supply chain rooted in technical expertise, rigorous planning, and people who care about getting it right. That’s why choosing the right manufacturing partner is as critical as the part itself.

Let’s discuss how to make your next mission ready. Start Your Project Today!