CNC Machining that Protects Your Bottom Line

Hartmann’s rise began with a simple promise: to make CNC machining smarter, faster, and more precise.

By blending advanced technology with expert craftsmanship, we deliver results that save time, reduce waste, and elevate quality.

<3% Scrap Rate

Minimize material waste

Up to ±0.0002" Tolerance

Get It Right The First Time

1 to 100,000+ Production Runs

Scale Without Compromise

Rigorous Quality Control

Zero Costly Rework

The Hartmann’s Advantage

Get a Complete, Turnkey Part

Hartmann’s is your one-stop shop—from engineering and machining to finishing and inspection. Every part leaves our facility complete, compliant, and production-ready. No outsourcing. No missing steps.

REDUCE PRODUCTION COSTS

Our <3% scrap rate means you pay for finished parts, not wasted material. ±0.0002″ tolerances held consistently eliminate costly rework and rejected parts.

ACCELERATE TIME-TO-MARKET

Multi-task CNC machining completes complex parts in single setups, significantly reducing production time. Live tooling delivers complete parts without secondary operations, getting your products to market faster.

SCALE CONFIDENTLY

One prototype or 100,000 production parts, our processes remain consistent. No quality degradation, no setup delays, no surprises.

ELIMINATE HIDDEN COSTS

In-house inspection catches issues before they ship. No field failures, no warranty claims, no damaged reputation.

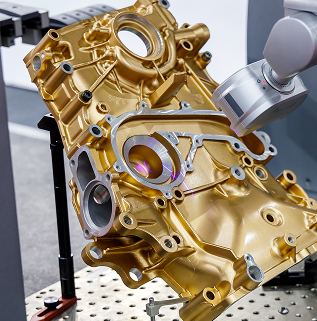

Advanced Machining Capabilities

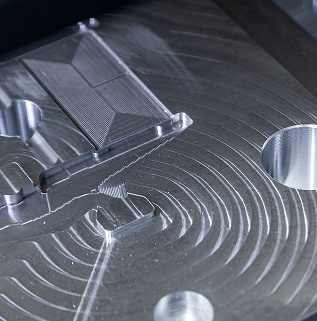

CNC MILLING

CNC MILLING

Our advanced milling capabilities deliver cost-effective precision on simple parts, maintaining exceptional accuracy on complex geometries, all while minimizing setup time and production costs.

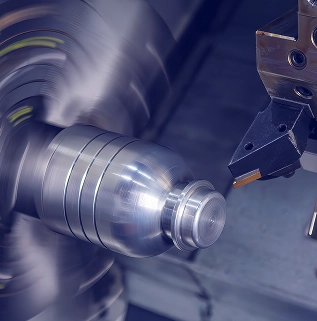

CNC MULTITASK TURNING

CNC MULTITASK TURNING

Complete parts in one operation. No transferring between machines, no secondary setups, no accumulated tolerances.

WIRE EDM

WIRE EDM

Machine hardened materials to final dimensions without heat distortion. Handle geometries impossible with conventional methods, achieving tolerances to ±0.0002″

FINISHING SERVICES

FINISHING SERVICES

Precision lapping and polishing deliver optical-grade surface finishes and exact flatness specifications.

CNC MILLING

Our advanced milling capabilities deliver cost-effective precision on simple parts, maintaining exceptional accuracy on complex geometries, all while minimizing setup time and production costs.

CNC MULTITASK TURNING

Complete parts in one operation. No transferring between machines, no secondary setups, no accumulated tolerances.

WIRE EDM

Machine hardened materials to final dimensions without heat distortion. Handle geometries impossible with conventional methods, achieving tolerances to ±0.0002″

FINISHING SERVICES

Precision lapping and polishing deliver optical-grade surface finishes and exact flatness specifications.

Material Expertise & Benefits

EXOTIC ALLOYS

Hastelloy, Inconel, nickel alloys, tungsten alloys, copper, and bronze. Specialized expertise gets difficult materials right the first time.

TITANIUM

Optimized tool life and cycle times protect your investment in this expensive material—delivering aerospace and medical-grade precision.

STEEL & STAINLESS STEEL

From carbon steel to duplex stainless steel—optimized parameters for each grade balance tool life, cycle time, and finish quality.

BRASS

Superior machinability means faster production and lower costs for electrical, mechanical, and decorative applications.

ALUMINIUM

Lightweight strength at lower material costs. Faster production, lower tooling costs, excellent surface finishes.

ENGINEERING PLASTICS

Hard plastics are machined with the same precision as metals.

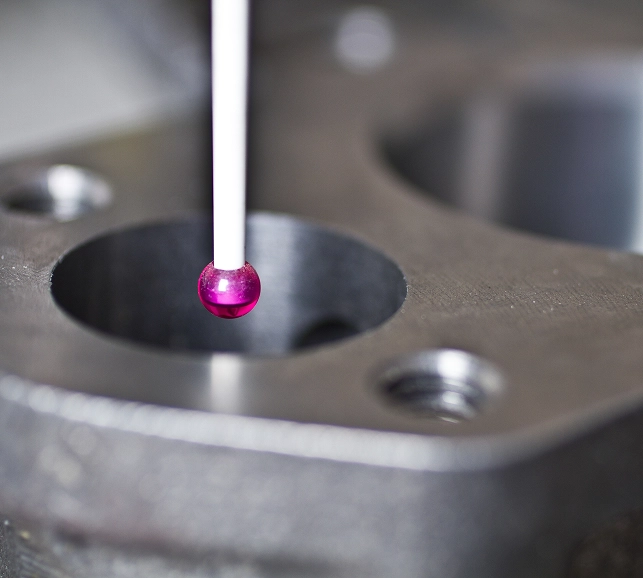

Quality Assurance

In-house CMM inspection and 3D laser scanning verify every critical dimension before parts ship. Complete dimensional data, material certifications, and traceability documentation for regulated industries. The result?

no production line stoppages.

no emergency re-orders.

Secondary Services

Hartmann’s provides the secondary services required to take your part from concept to production-ready — all coordinated through a single, accountable team. We manage every step, align timelines, verify quality, and ensure your final parts arrive exactly as required.

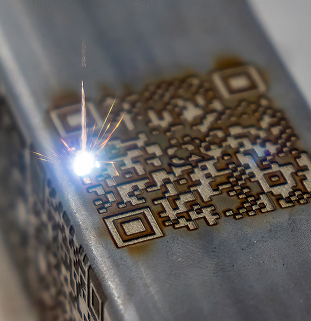

LASER ETCHING

LASER ETCHING

High-precision, permanent marking for traceability, compliance, branding, and serialization—ensuring every part ships fully identified and production-ready.

METAL FABRICATION

METAL FABRICATION

Comprehensive metal fabrication support for custom components and assemblies, delivering the strength, durability, and performance your application requires.

REBUILDS

REBUILDS

Hartmann’s has been rebuilding engines and other complex parts since our first day in 1955. No matter the size, complexity, or current status of your rebuild project, our engineers will get you running at maximum efficiency.

METAL FINISHING

METAL FINISHING

We provide a wide range of finishing solutions, from coatings and passivation to polishing and specialty surface treatments, engineered to meet your specific durability, corrosion, electrical, or visual requirements.

WELDING

WELDING

High-quality welding for simple to complex assemblies, meeting the performance standards demanded by aerospace, energy, medical, and commercial environments.

ENGINEERING & CAD

ENGINEERING & CAD

Engineering support to optimize performance, improve manufacturability, and accelerate time-to-production. CAD modeling, design support, and DFM guidance provided by experienced engineers.

REVERSE ENGINEERING

REVERSE ENGINEERING

Hartmann’s is so confident in its engineering expertise that we make partnering with us as simple as possible. You give us the part you need replicated, and we’ll figure out the most efficient way to manufacture it. Guaranteed.

LASER ETCHING

High-precision, permanent marking for traceability, compliance, branding, and serialization—ensuring every part ships fully identified and production-ready.

METAL FABRICATION

Comprehensive metal fabrication support for custom components and assemblies, delivering the strength, durability, and performance your application requires.

REBUILDS

Hartmann’s has been rebuilding engines and other complex parts since our first day in 1955. No matter the size, complexity, or current status of your rebuild project, our engineers will get you running at maximum efficiency.

METAL FINISHING

Precision lapping and polishing deliver optical-grade surface finishes and exact flatness specifications.

WELDING

High-quality welding for simple to complex assemblies, meeting the performance standards demanded by aerospace, energy, medical, and commercial environments.

ENGINEERING & CAD

Engineering support to optimize performance, improve manufacturability, and accelerate time-to-production. CAD modeling, design support, and DFM guidance provided by experienced engineers.

REVERSE ENGINEERING

Hartmann’s is so confident in its engineering expertise that we make partnering with us as simple as possible. You give us the part you need replicated, and we’ll figure out the most efficient way to manufacture it. Guaranteed.

Ready to Reduce Costs and Accelerate Production?

Every mistake costs money. That’s why our precision eliminates rework, scrap, and delays before they happen. With parts that arrive on time and to spec, you save on labor, materials, and downtime—boosting profitability from the first order.

LET’S DISCUSS HOW HARTMANN’S CNC MACHINING could deliver MEASURABLE ROI FOR YOUR PROJECT.